When you buy a yak wool scarf from us, the wool has come a long way. It has been washed several times, loaded into trucks and planes to keep you cozy and warm. The special thing: We can tell you exactly where the wool comes from and which stations it went through.

Station 1: Between yaks and yurts

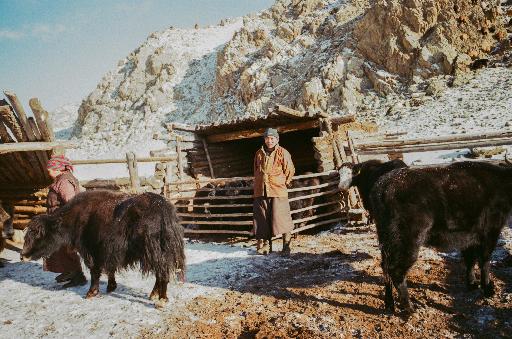

It is in these snow-covered winter landscapes of the Okhon Valley that our supply chain begins. With nomads like Muugii and his family, who spend the winter in the lee of the mountain landscape with their herd of yaks. Beneath their feet, the frozen Orkhon River meanders through the valley, lined with dense forests, rolling hills and pastures that glow green in summer. Small yurts can be seen here and there, harmoniously blending into the natural surroundings. Muugii's parents live in one such yurt, built of wood and thick fur and heated by coal and dried manure. They live on milk, meat and the wool of their animals.

Here in the Orkhon Valley live about 40 nomadic families with some goats, sheep and approximately 70 yaks. They are masters in herding yaks and collecting their wool as soon as the snow has melted. With deft hands, Muugii comb the loose fur from the yak hair and collect it. The wool is then taken to the nearest Aimag - the provincial center - and sold in kilo bags to the highest bidding wool traders. The work is physically demanding and one yak produces only about 500 grams of raw wool. But the natural fibers are of particularly high quality. By nature they are soft to the touch, naturally water repellent, breathable and temperature regulating, making them ideal for making winter garments. This is another reason why the sacks of raw wool are now making their way to the Mongolian capital.

Station 2: Dehairing, washing, spinning

The production of wool products from yak wool is a careful and demanding process that involves several steps. At a family-owned factory in Ulaanbaatar, the yak wool is usually sorted, cleaned and spun by machine before being prepared for further processing.

The first step in production is sorting the raw wool. The wool is sorted by color, length and quality to ensure that only the best fibers are used for further processing. Subsequently, it is machine washed to remove all impurities. Once the wool is cleaned and sorted, it is spun by machine. Modern spinning machines complete this step quickly and precisely. The wool is processed into fine threads, which are then made into fabrics on looms.

Finally, the fabrics are processed in the factory into various wool products such as sweaters, hats and scarves. This is often done by using modern machines operated by experienced workers. The wool products are then carefully inspected to ensure that they meet the high quality standards expected by our producers. The entire process of yak wool production is an important industry in the region and contributes to the sustainability and protection of the nomads' traditional way of life.

Step 3: A long journey

After our wool products are manufactured and finalized, they are packed and brought from Mongolia to Germany by plane. Six years ago, when Malte started importing wool socks, it was just a handful of packages that he picked up at Cologne airport. Today, a shipping company brings the boxes from the airport to our store in Aachen. This is where our supply chain ends. The yak wool is unpacked, inspected by us and sorted into the warehouse. What happens to it then is up to you and our employees. But that is a story for another time.

Overall, yak wool is a unique natural fiber that comes from the coexistence of yaks and nomads in Mongolia, and through the skills of our producers, becomes beautiful wool products against the cold. A short global supply chain that brings you a piece of Mongolian skill in your wardrobe.

Supply chain: How does our yak wool get to Germany?